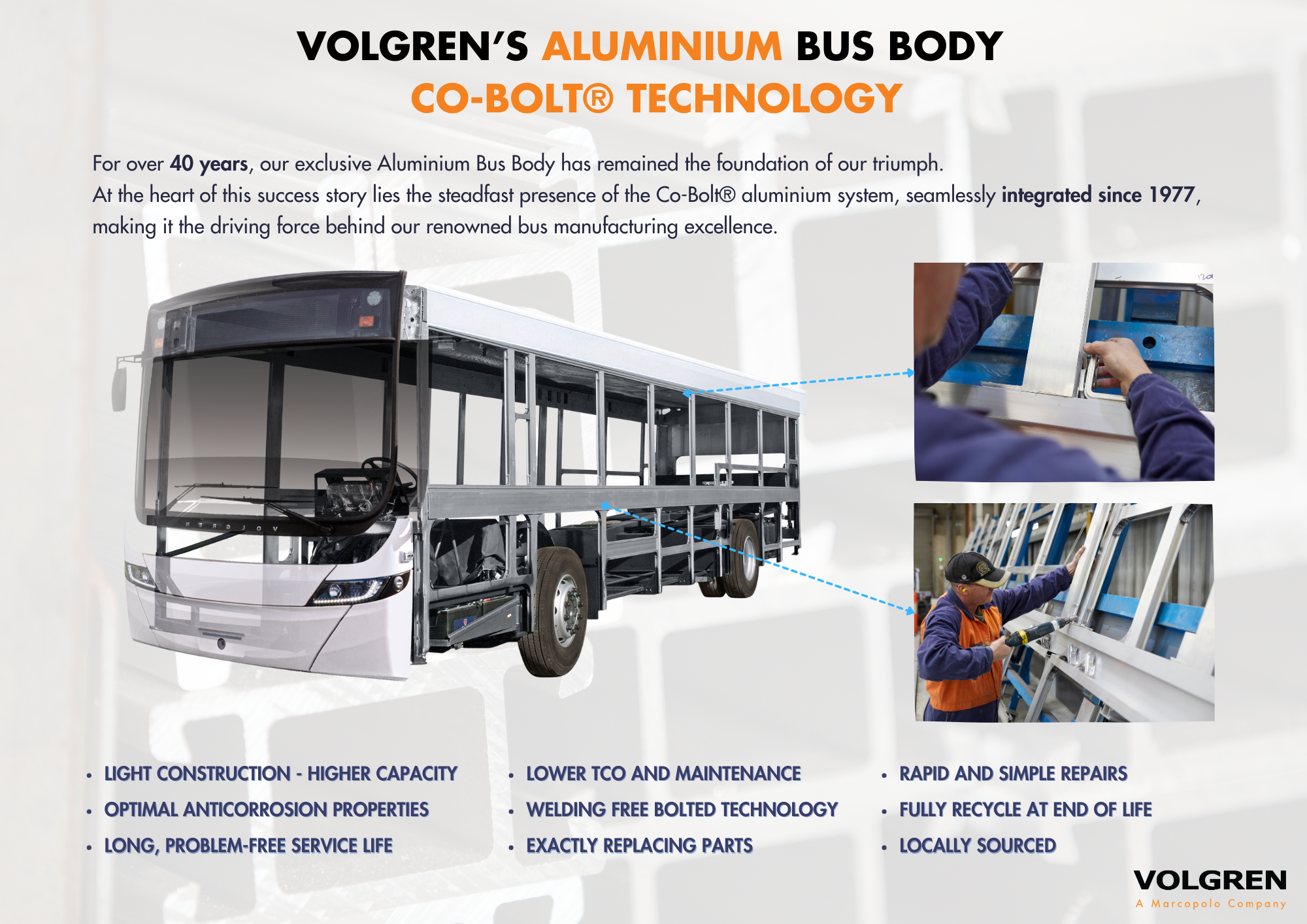

Since its integration into our manufacturing processes in 1977, Our Aluminium Bus Body has been a cornerstone of our success. Central to this achievement is the enduring presence of the Co-Bolt® aluminium system. This innovative system has not only stood the test of time but also continues to play a pivotal role in shaping our continued accomplishments.

The lightweight properties of aluminium are the backbone of our Aluminium Bus Body’s exceptional efficiency. By using lightweight aluminium, these buses consume less fuel, leading to significant operational cost savings. With a smaller ecological footprint, our aluminium buses play a role in reducing the overall environmental impact of public transportation.

One of the key advantages of the Aluminium Bus Body is its modular and non-welded structures, including the game-changing Co-Bolt® Technology with its bolted aluminium joints. This innovative approach not only makes repairs easier and more cost-effective than traditional welded bodies but also ensures swift repairs, reducing downtime and keeping fleets in service. The anti-corrosive and resistant properties of Aluminium further enhance the durability, aligning perfectly with the requirements of Australian buses that must remain on the road for two decades or more. This results in minimal downtime for operators, allowing them to serve passengers efficiently and reliably for extended periods. Additionally, the lightweight construction enables increased passenger capacity without compromising safety or comfort, further optimizing the efficiency of these buses.

The core of our Aluminium Bus Body design revolves around sustainability, aligning perfectly with Volgren’s commitment to a greener future. Aluminium, highly recyclable and environmentally friendly, lies at the heart of this approach. This commitment is underscored by a Monash University study, which delved into the advantages of opting for our flagship bus. This comprehensive analysis not only revealed over $60,000 in operational savings over the bus’s lifespan but also highlighted the substantial environmental benefits. Through reduced fuel consumption, energy usage, and overall environmental impact, operators contribute significantly to environmental stewardship.

Our dedication to sustainability shines through our robust recycling practices. We take a responsible approach to materials management, including aluminium, steel, plastics, and timber, all of which undergo recycling processes that minimize environmental impact while bolstering local industries. Notably, an impressive 73% of materials used in Volgren’s bus body can be recycled, with an additional 3% suitable for reuse or further breakdown. This commitment extends to diverse elements, from electronic waste to paint, oil, and even fire extinguishers, exemplifying our comprehensive approach to environmentally responsible manufacturing.

Furthermore, the adaptability of our Aluminium Bus Body is tailored to suit the specific requirements of diverse operators. Whether it’s adjusting seating configurations, optimising storage space, or incorporating specific amenities, our buses can be tailored to deliver a personalised solution for every customer. This customer-centric approach ensures that the buses meet specific operational requirements while enhancing passenger satisfaction.

In addition to our superior products, we’re proud to support local jobs and use nearby suppliers for raw materials, contributing to community growth. Choosing our aluminium bus bodies means more than getting an efficient product; you’re also backing local businesses and jobs. Beyond manufacturing, our commitment extends to excellent support services, including our after-sales departments across the nation. This team ensures customer satisfaction and maintains lasting relationships by providing maintenance, repair, and technical assistance, enhancing both your ownership experience and local employment opportunities.

With its Co-Bolt® Technology, our Aluminium Bus Body redefines transportation norms.

Lightweight, sustainable, and versatile, it’s a beacon for greener transit.

Join us in steering towards a future where innovation drives both environmental preservation and economic growth.